5-S Game Set and 5-S Simulation

This full day event focuses on preparing the factory or office for visual control. Participants are provided with the 5-S philosophy, tools and strategies as developed by the Toyota Motor Company.

After the familiarization presentation, the students are invited to participate in a series of fun games which repeat and focus the concepts and terms. See 5-S Game Set on the Team Development product page for details.

Next the participants set up a simulated factory, complete with a large plastic sheet on which a factory floor plan is created using color tape and markers, with inventory areas and work bench areas outlined. The kit includes two real products (Product A and Product B) to assemble, and all of the tools, tapes, labels and equipment necessary to implement and practice the strategies of 5-S.

The 5-S Training presentation is interactive, and is presented during the hands-on simulation. Each of the "S" strategies is presented in theory, examples shown, and then the students practice the "S" with the simulation. This repeats until the team has completed all 5 "S's"

Complete training is both possible and practical in the classroom setting. Students get comfortable with their decision making and developing the confidence levels necessary to implement 5-S before they step foot in their real work area.

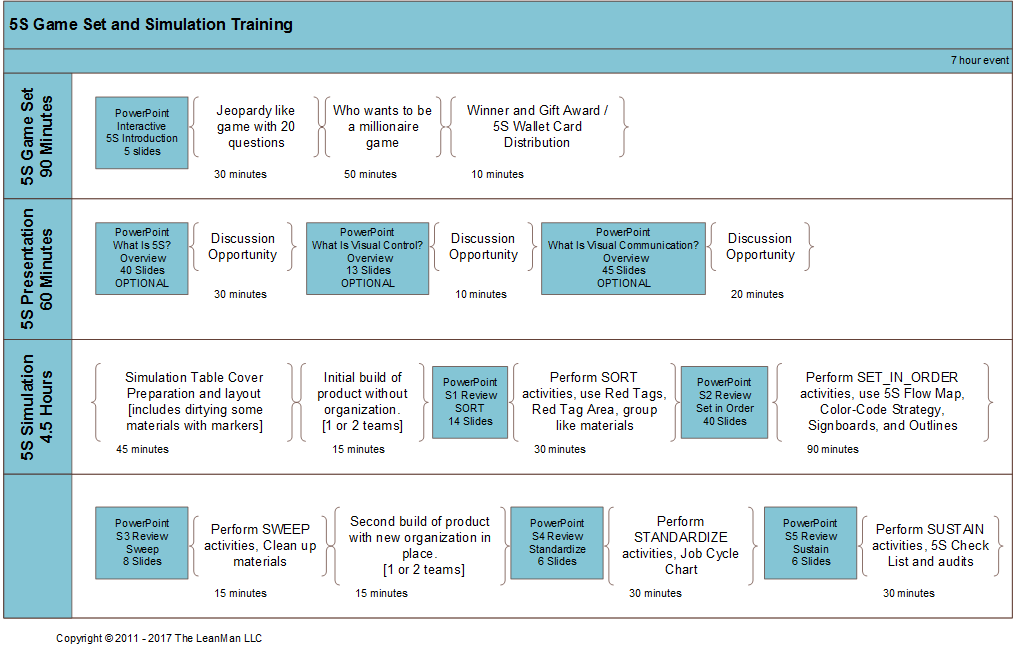

THE EVENT

A detailed step-by-step 80-page PowerPoint 5-S Review presentation provides a full discussion of each of the five S steps, focusing on the strategies and tools of each S. The presentation is menu driven which allows the facilitator to easily navigate to the sections and strategies of interest. The 52-page Facilitator Guide is designed to be complimentary to the 5-S Review, and is used to guide the interactive exercises by referencing the appropriate Review section as the simulation progresses. The Review is halted at each point, and the team practices the S step and its strategies throughout the interactive event. Laminated practice forms and wet-erase markers provide the opportunity to experiment with strategies such as the 5-S Flow Chart, Color-coding plan, Painting, Outlining, Sign boarding, 5-S Job Cycle Chart, workspace layout and shadow boards before applying the techniques to the simulated factory workspace.

NUMBER OF PARTICIPANTS

The simulation requires at least two participants to assemble the products and two or three others to implement the 5-S strategies as a minimum. The event can easily be held with larger groups up to 25 participants for the training presentations and games, then split into a series of smaller teams to practice the simulation with the products.

EVENT TIME

Event time is 90 minutes for the 5-S Game Set followed by 30 to 60 minutes of 5-S familiarization presentation, followed by 4 to 5 hours hands on simulation time. Room size should be small to large conference room depending on the number of participants during the games.

5-S Simulation Training Kit and 5-S Game Set