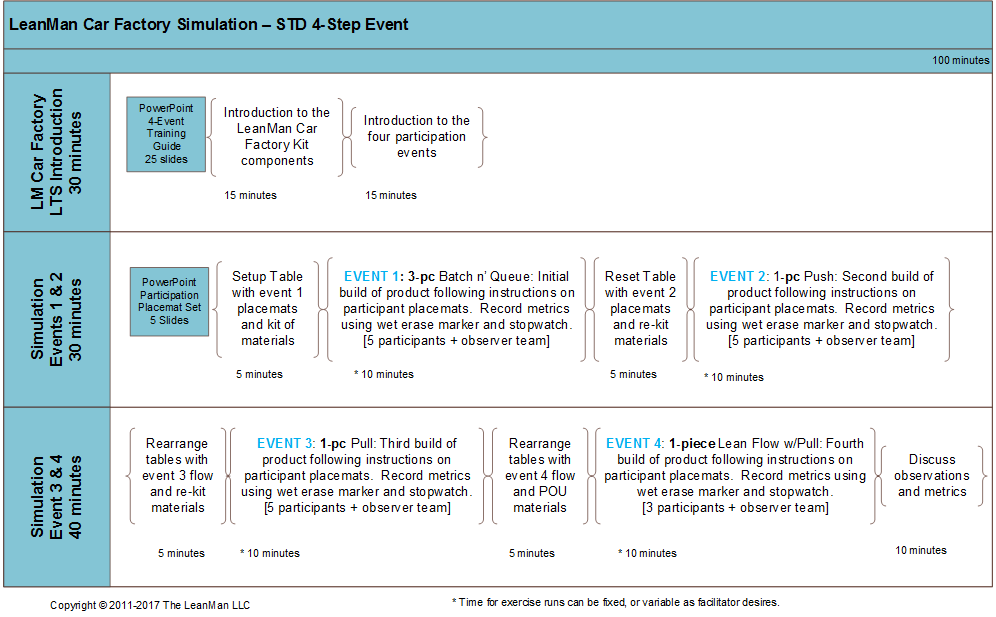

4-Step Car Factory Simulation

This 4-step simulation is the standard simulation event and uses one car factory kit per team. Add a few more Companion Car Factory Kits and a single facilitator can easily run 2 or 3 teams for a little competition.

This simulation event is targeted toward people who work in a team or who want to spend a little more time discovering the differences in the four main flow methods.

The first simulation step, Batch 'n Queue, and the last, Lean Flow, are similar to the executive event Learning to See the Waste 2-step event. The middle two simulations explore the conversion from Batch 'n Queue to a Work Cell push flow, a discussion about the results and what was gained, and then the conversion again to a One-Piece Continuous Flow with pull and again a discussion about the additional results and gains.

The final conversion to a Lean Customer-Demand Pull introduces the concepts of customer demand, and flow regulators such as kanban squares with min/max levels and visual signal devices.

This simulation is usually customized by you so you can focus on your company's specific needs. The placemat instruction sets are on the USB drive as a file that you can edit to add your changes, and then print and use to suit your needs.

NUMBER OF PARTICIPANTS

The team set up is 5 people for each simulation and two or three observers, all of which rotate positions with each event, for a total of 8 people with hands-on participation per car kit. During the simulation, the non hands-on people perform the 10-Second Test (provided only with the Deluxe Car Factory Kits) and watch the event for later discussion on the differences in flow and in non value-adding activities observed. Others perform the conveyance task of moving totes, containers and materials between the departments.

EVENT TIME

A single facilitator can easily control two or three teams running simultaneously when using the participant instruction placemats. Requires one Car Factory Kit for each team.

Event time 70 minutes for the 4 simulation steps and time for discussion on observations about the flow and NVA waste, plus allow another 30 minutes for the PowerPoint presentations. Room size should be medium conference room with enough table space to allow the simulation room to spread out. Ideally, the Stockroom and Inspection at one table, the Assembly Departments at a second table, and the Customer at a third.

Companion Car Factory Simulation

Deluxe Car Factory Simulation

The Deluxe Kit covers all the basics of learning Lean, including 2-Step, 3-Step, 4-Step and a 5-Step Set of exercises, each digging deeper into the fundamentals.

Deluxe PLUS VSM Car Factory Simulation

Deluxe PLUS HEIJUNKA Car Factory Simulation

Deluxe PLUS KANBAN Car Factory Simulation

The Kanban Simulation integrates two great products into two single deep containers, or if you prefer, one single double-deep container, providing an excellent training range from beginner to advanced.

LeanMan Grand Car Factory Simulation

Deluxe Double Car Factory Simulation